Viewed products

-

Spherical Tantalum...

Spherical tantalum (Ta) powder is...

Spherical Powder

- Products

- Deposition Materials

- Refractory Metals

- Rare Earth Materials

- Powder

- Technical Ceramics

- Lanthanum Hexaboride (LaB6) Materials

- Pyrolytic Boron Nitride (PBN) Products

- Boron Nitride (BN) Products

- Alumina Ceramics (Al2O3)

- Aluminum Nitride (AlN) Products

- Silicon NItride (Si3N4) Ceramics

- Silicon Carbide (SiC) Ceramics

- Graphite Products

- Zirconia Ceramic

- MAX Phase Ceramic Materials

- Boron Carbide Ceramics (B4C)

- Magnesium Oxide Ceramics (MgO)

- Quartz Ceramics

- Macor Machinable Glass Ceramic

- Beryllium Oxide (BeO) Ceramics

- Piezoelectric Ceramics

- High Purity Materials

- Precious Metals

- Chemicals

- Crystals & Substrates

- Applications

- Other

Spherical Tantalum (Ta) Powder

ME73-SP

New product

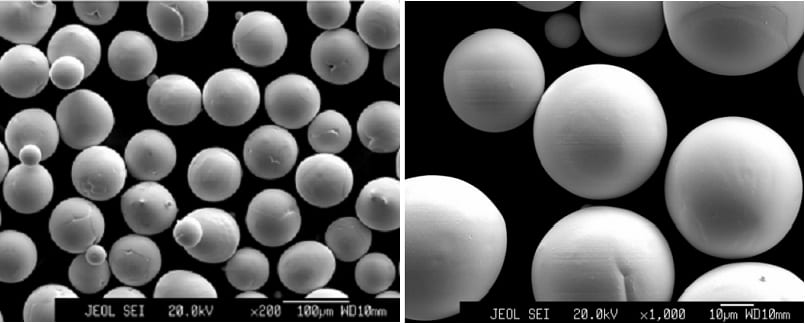

Spherical tantalum (Ta) powder is made by RF plasma spheroidization, which has high purity hypoxia, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, and high loose density and vibrational density. We can provide a purity of 99% ~ 99.99%. The purity and particle size can be tailored according to specific requirements.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

Data sheet

| Shape | Spherical / Ball Powder |

| Particle Size | 1-5μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, customized |

| Molecular Formula | Ta |

| Molecular Weight | 180.94 g/mol |

| Purity | 99.99%/99.9%/99% |

| CAS | 7440-25-7 |

More info

Spherical Tantalum (Ta) Powder is widely used in aviation, aerospace, nuclear energy, medical equipment, and other industries. HM is a professional supplier and manufacturer of tantalum powder, specializing in customized particle sizes of spherical tantalum powder with low oxygen content, tailored to meet customer demands.

Spherical Tantalum (Ta) Powder Specifications

Product | Chemical Composition(%) | ||||||||||

Ta | Fe | Si | Ni | Ti | Mo | W | Nb | ||||

HM-Spherical Ta | >99.98 | <0.001 | <0.005 | <0.002 | <0.001 | <0.001 | <0.01 | <0.01 | |||

Gas Impurities (%) | |||||||||||

C | H | O | N | ||||||||

≤0.003 | ≤0.0015 | ≤0.03 | ≤0.004 | ||||||||

Density (g/cm3) | Hall Flow Rate (s/50g) | ||||||||||

Apparent Density | Tap Density | Value | |||||||||

>9.5 | >10.5 | ≤6.5 | |||||||||

Particle Size | 1-5μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, or customized. | ||||||||||

Particle Size Description

- 1-5μm

- 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

- 15-45μm (D10=15~20μm,D50=25~30μm,D90=35~40μm)

- 15-53μm (D10=15~20μm,D50=25~35μm,D90=45~50μm)

- 45-75μm (D10=45~55μm,D50=55~65μm,D90=70~75μm)

- 45-105μm (D10=50~60μm,D50=75~85μm,D90=95~105μm)

- 75-150μm (D10=80~90μm,D50=110~125μm,D90=135~150μm)

1-10 μm PSD 5-25 μm PSD

Spherical Tantalum (Ta) Powder Properties

- High purity

- Low oxygen

- High sphericity

- Smooth surface

- No satellite spheres

- Uniform particle size distribution

- Excellent flow properties

- High bulk density and tap density

Spherical Tantalum (Ta) Powder Applications

- Used in metal injection molding (MIM)

- Used in laser/electron beam additive manufacturing (SLM/EBM, 3D printing)

- Used in thermal spray (TSA)

- Used in powder metallurgy (PM)

Spherical Tantalum (Ta) Powder Storage and Packaging

Spherical Tantalum (Ta) Powder should be stored in a sealed container in a dry and cool place, and should not be exposed to air for an extended period of time. We offer vacuum-sealed packaging including 100g/bag, 500g/bag, 1kg/bag, and 25kg/drum, or we can offer customized packaging as per specific requirements.

Related Products

Inquiry to Heeger Materials

Items marked with an asterisk (*) are required.

Heeger Materials respects your privacy, and we will NOT sell or provide your personal data to other third parties, or allow them to use your personal data for their own purposes. However, we would like to send you information from time to time by mail or email about our products and special offers in addition to the interest categories you've selected above. Read our Privacy Policy