Viewed products

-

Spherical...

Spherical Cobalt-Based Alloy Powder...

View larger

View larger Spherical Powder-Cobalt Based Alloys (CoCrMo)

SP-1252

New product

Spherical Cobalt-Based Alloy Powder (CoCrMo) are widely used in the medical field because of their excellent corrosion resistance, mechanical properties, and biological properties. Our powder has the characteristics of high sphericity, good fluidity, high purity, large loose density, full density inside particles, and no hollow powder.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

Data sheet

| Shape | Spherical / Ball Powder |

| Particle Size | 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, customized |

| MF | CoCrMo |

More info

Spherical Cobalt-Based Alloy Powder (CoCrMo) is a hard alloy that can resist various types of wear and corrosion as well as high-temperature oxidation. HM provides high-quality Spherical Cobalt-Based Alloy Powder (CoCrMo) at a competitive price, which can be used in Scientific research or industrial production.

- Material: CoCrMo

- Particle Shape: Spherical

Spherical Cobalt-Based Alloy Powder Chemical Composition

Element | Min [%] | Max [%] |

Co | Bal. | Bal. |

Cr | 27 | 30 |

Mo | 5 | 7 |

W | - | 0.2 |

Si | - | 1.0 |

O | - | 0.10 |

Spherical Cobalt-Based Alloy Powder Characteristics

- High powder sphericity

- Smooth surface

- Fewer satellite balls

- Low oxygen content

- Uniform particle size distribution

- Good fluidity

Spherical Cobalt-Based Alloy Powder SEM

Spherical Cobalt-Based Alloy Powder Applicable processes

According to its application, cobalt base alloy can be divided into cobalt-base wear-resistant alloy, cobalt-base high-temperature resistant alloy cobalt base wear resistance, and aqueous solution corrosion alloy. General working conditions, in fact, are both wear resistance and high-temperature resistance or wear resistance and corrosion resistance, some working conditions may also require high-temperature resistance and wear resistance and corrosion resistance, and the more complex working conditions, the more can reflect the advantages of cobalt-based alloy.

Spherical Cobalt-Based Alloy Powder Application

- Used as a human joint implant material.

- Used as a high-temperature, wear-resistant, and impact-resistant component of gas turbines.

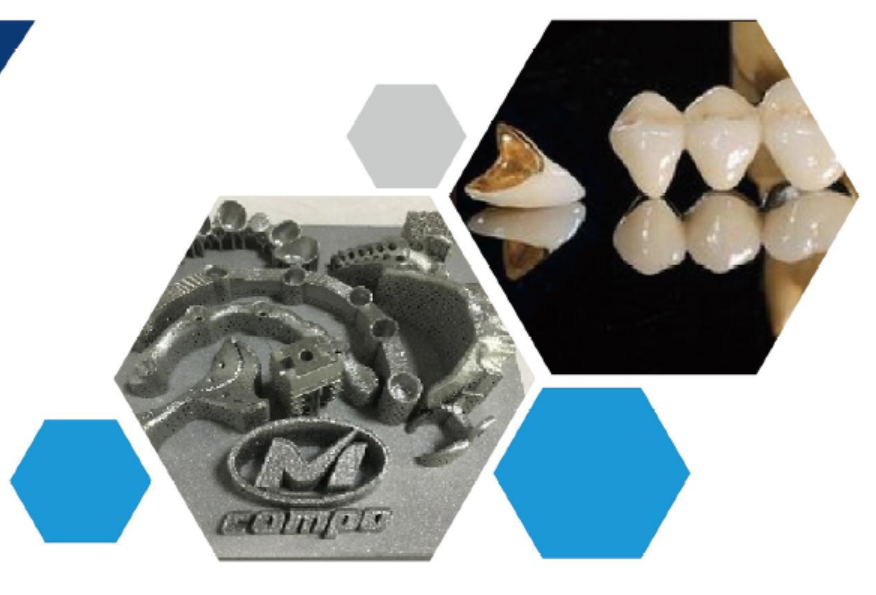

- Used as the main material of dental inner liner.

- Used as a metal material for the 3D printing industry.

- Used for the production of guide vane and nozzle guide vane of aviation jet engines, industrial gas turbines, naval gas turbines, diesel nozzles, etc.

Particle Size Description

- 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

- 15-45μm (D10=15~20μm,D50=25~30μm,D90=35~40μm)

- 15-53μm (D10=15~20μm,D50=25~35μm,D90=45~50μm)

- 45-75μm (D10=45~55μm,D50=55~65μm,D90=70~75μm)

- 45-105μm (D10=50~60μm,D50=75~85μm,D90=95~105μm)

- 75-150μm (D10=80~90μm,D50=110~125μm,D90=135~150μm)

Spherical Cobalt-Based Alloy Powder Packaging

Spherical Cobalt-Based Alloy Powder (CoCrMo) should be stored in a sealed container in a dry and cool place, and should not be exposed to air for an extended period of time. We offer vacuum-sealed packaging including 100g/bag, 500g/bag, 1kg/bag, and 25kg/drum, or we can offer customized packaging as per specific requirements.

Inquiry to Heeger Materials

Items marked with an asterisk (*) are required.

Heeger Materials respects your privacy, and we will NOT sell or provide your personal data to other third parties, or allow them to use your personal data for their own purposes. However, we would like to send you information from time to time by mail or email about our products and special offers in addition to the interest categories you've selected above. Read our Privacy Policy