Viewed products

-

CuCrZr Spherical...

CuCrZr Spherical Copper Alloy Powder...

CuCrZr Spherical Copper Alloy Powder

SP-1290

New product

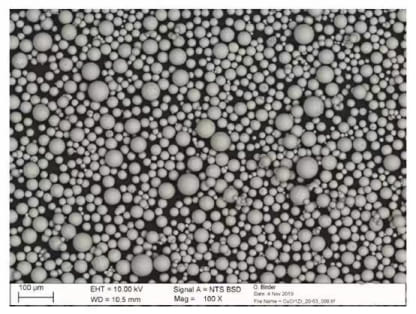

CuCrZr Spherical Copper Alloy Powder is a hardenable copper alloy, which combines high strength and hardness with very low thermal resistance. It has good thermal and electrical conductivity.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

Data sheet

| Thick | 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm, customized |

| Shape | Spherical / Ball Powder |

| MF | CuCrZr |

More info

CuCrZr Spherical Copper Alloy Powder has excellent properties that make it useful for machinery construction and electrical applications, mold cooling inserts, and high-performance applications in the aerospace or automotive industry.

CuCrZr Spherical Copper Alloy Powder Specifications

Product | Chemical Composition(wt%) | |||||||

Cu | Cr | Zr | Fe | Si | O | N | ||

CuCrZr

| Balance | 0.5-1.2 | 0.03-0.3 | <0.08 | ≤0.1 | ≤0.05 | ≤0.05 | |

Physical Properties | ||||||||

Particle Size Distribution | Apparent Density (g/cm3) | Hall Flow Rate (s/50g) | ||||||

| D10 | D50 | D90 | |||||

15-53 μm | 15 μm | 30 μm | 45 μm | ≥4.1 | ≤15 | |||

45-105 μm | 58 μm | 76 μm | 102 μm | ≥4.6 | ≤20 | |||

Note | The particle size is 5-25μm, 15-53μm, 45-105μm, 75-150μm, or customized. | |||||||

CuCrZr Spherical Copper Alloy Powder Properties

- High powder sphericity

- Smooth surface

- Fewer satellite balls

- Low oxygen content

- Uniform particle size distribution

- Good fluidity

- High bulk density and tap density

CuCrZr Spherical Copper Alloy Powder Production

We developed a unique powder production process to provide perfect spherical powders. Any metal or alloy can be atomized according to your needs. Our processes are run with Argon as atomization gas in a dust-free production environment to guarantee maximum product quality. Any process (production, classifying, screening, packaging) can be done under Argon 5.0, so oxygen-free production can be guaranteed.

CuCrZr Spherical Copper Alloy Powder Applications

- Used in the production of valves, bearings, gears, and other high-stress components.

- Use in injection molding, powder metallurgy, and other forming processes.

- Used in marine, chemical, and nuclear applications.

- Used in gas turbines, jet engines, and other high-temperature systems.

- Used in medical implants and devices without causing adverse reactions.

CuCrZr Spherical Copper Alloy Powder Storage and Packing

Spherical CuCr1Zr Copper Alloy Powder should be kept sealed and stored in a dry and cool place, avoiding exposure to air for a long time. The vacuum-sealed packing is 100g/bag, 500g/bag, 1kg/bag, 25kg/drum, or as required.

Other Copper Based Alloys

Copper Based Alloys | ||

Standard | Nominal Composition | Application |

C70320 CW112C | CuNi3Si | High Conductibility |

C18000 CW111C | CuNi2SiCr | High Conductibility |

C18150 CW106 | CuCrZr | Wear Resistance |

OFHC Cu | Cu 99.99% O<300 ppm | Highest Level of Purity |

OFHC Cu | Cu High Oxygen | Modified for Specific Laser |

CWx (Modified) | Adjusted Composition | Customer Specific |

Inquiry to Heeger Materials

Items marked with an asterisk (*) are required.

Heeger Materials respects your privacy, and we will NOT sell or provide your personal data to other third parties, or allow them to use your personal data for their own purposes. However, we would like to send you information from time to time by mail or email about our products and special offers in addition to the interest categories you've selected above. Read our Privacy Policy